|

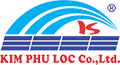

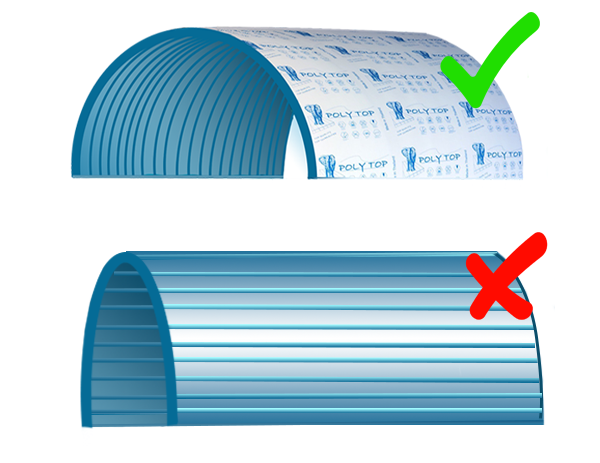

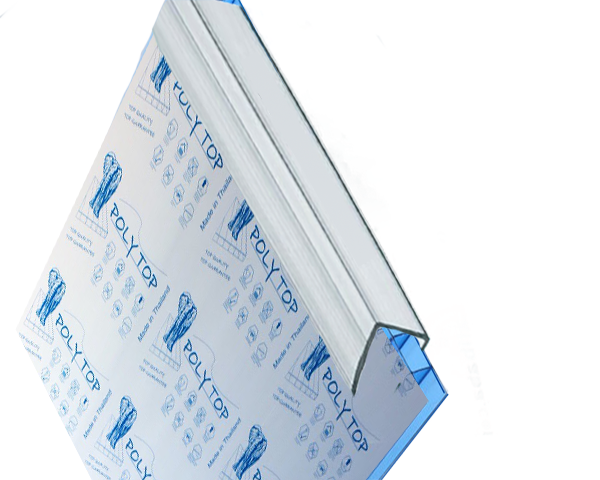

1. - The light and radiant energy from the sun has a harmful effect on polycarbonate. Multiwall polycarbonate features a UV-protected surface on one or both sides of the sheet. This UV protection prevents ultraviolet rays from deteriorating the polycarbonate, ensuring the sheet will not crack, yellow, or weaken from intense sun exposure. When installing multiwall polycarbonate, it is important to have the UV-protected surface facing up or towards the sun. Note: The masking film on the polycarbonate sheet indicates which side of the sheet is UV protected. |

||||||||

|

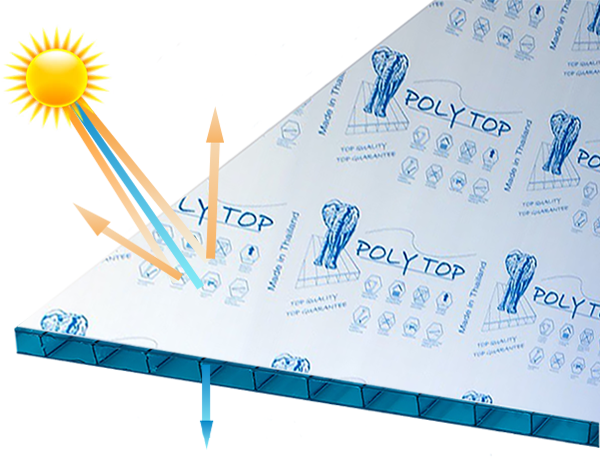

2. - It would be better to use a cutter. Lay this sheet on a flat surface and care should also be taken to avoid scratching the sheets when handling. - The circular saw should not be used because the dust will fly inside the hollow of the sheet. It's look dirty and ugly. |

||||||||

|

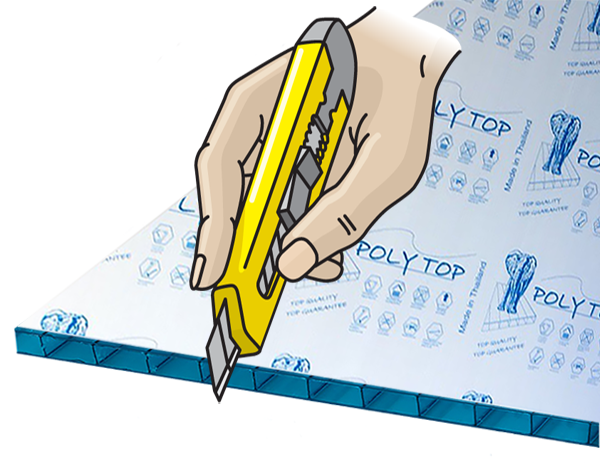

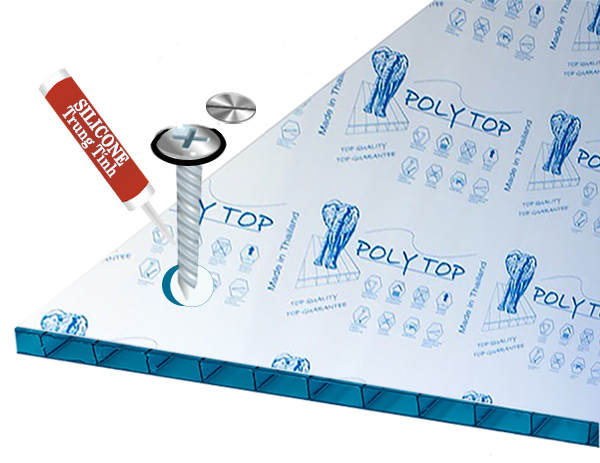

- Holes should be drilled at the range of 2 mm from the diameter of fasteners as this allows for thermal expansion during noontime and contraction at night. - All holes must be drilled at least 40mm from the edge of sheet |

||||||||

|

- when screwing, must use rubber gaskets. - NEVER USE PVC gaskets. PVC is incompatible with polycarbonate, and will harm the panel. Damage caused by this will nullify the warranty. - After installing profiles, a thin bead of sealant may be used to keep out air, moisture, dirt, and debris but is not typically necessary. The use of a sealant is only recommended for sealing points where the sheet meets an exterior wall. Note: Only use a 100% silicone sealant. Other types of caulking or sealants may attack the sheet. Always check the product label to ensure sheet compatibility. |

||||||||

|

- When cold-bending multiwall polycarbonate, the flutes (ribs or channels) should follow the curve of the sheet. Sheets can be bent in a variety of diameters. Maximum bending radius is in accordance with sheet thickness. - Bend sheet longitudinally, never across sheet width. - Bending the sheet lengthwise maintains its sheet strength and ensures proper drainage. - Avoid over tensing the sheet. Do not flex or install sheets to the point of buckling.

|

||||||||

|

|

||||||||

|

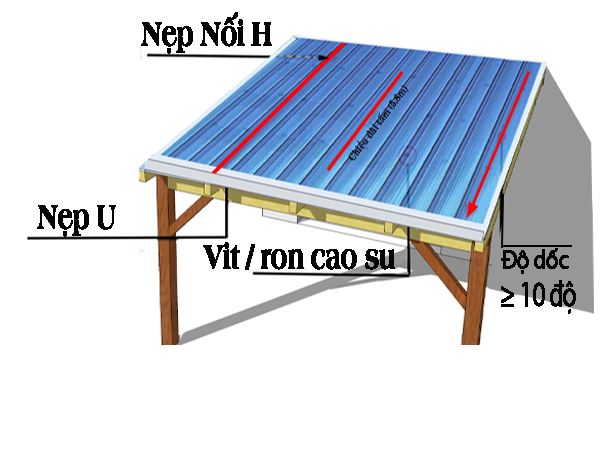

7. - Before building your structure, you will want to determine the pitch of your roof. The slope or angle of a roof is referred to as the pitch. Beyond aesthetics, the main purpose of a roof’s pitch is to shed water, snow, and other debris from the roof. - The pitch of a roof is calculated by the number of cm it rises vertically for every 30 cm it extends horizontally. - Snow, wind, and weather loads should always be considered when determining your roof pitch. - A low roof pitch may require additional sealing to ensure weather resistance. - To ensure proper drainage of roofing systems, a minimum slope of 2:12 is recommended. (10o) |

||||||||

|

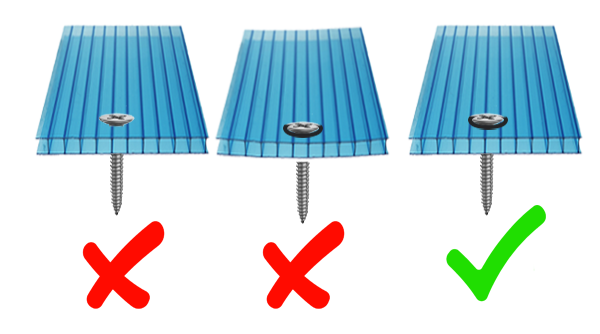

- Do not overtighten screws. Overtightened screws may cause sheet to dimple. A correctly installed fastener will sit flush against the sheet - After screwing points, it may be sealed with a thin bead of 100% neautral silicone.

|

||||||||

|

- The U Polycarbonate profile is designed to seal the edge of the polycarbonate sheets. Applied after the solid/vented aluminum tape it close the edge to prevent dust, water and bug get access to the hollow space. It also provide a a clear finish to the edge of the sheet - In order to prevent dust and dirt penetrating inside the ribs, the exposed top and bottom ends (the width side of a sheet) must always be sealed first with U profile on the top and at the bottom. |

||||||||

|

10. - All sheets are protected with a special film that protects the material from scratches during loading and unloading, transportation and installation. It is recommended to remove it immediately after installation in order to prevent its tight adhesion to the material, which in the future will make the process of its removal rather problematic. |

3.

3.  4.

4. 5.

5.  6.

6.

8.

8. 9.

9.