|

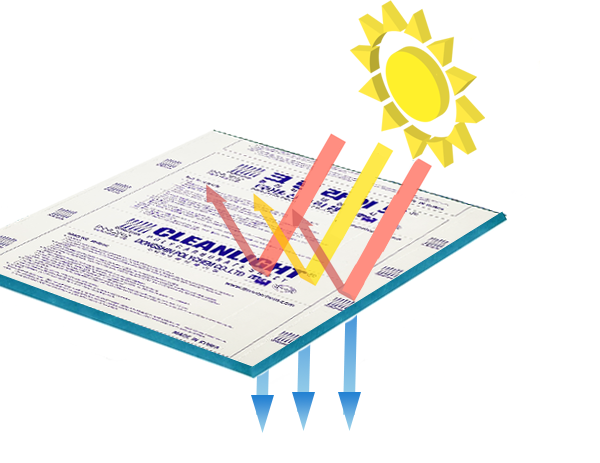

1. - This is the most crucial step. Polycarbonate sheets come with a special UV protective layer on only one side of the sheet. Thus, it is very important to install this side up so that you can take benefit of this property. If you use it the other way , you won’t be able to take the benefit.

- So, you must face the printed PR film rise up to the sun.

|

||||||||||||||||||

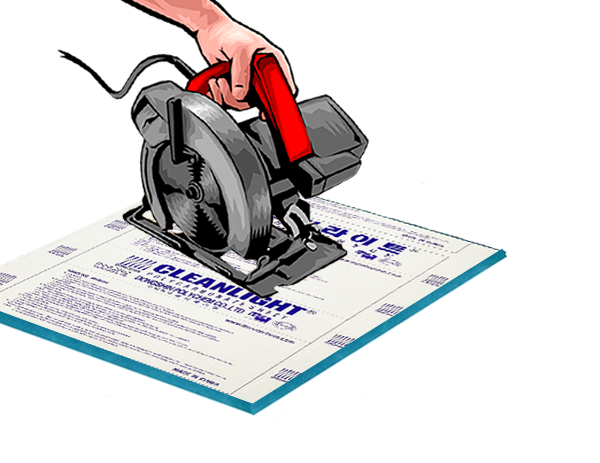

2. Cut

When cutting larger lengths of polycarbonate, a circular saw makes for the best choice. It will result in a cleaner and accurate cut. Also, polycarbonate is quite insensitive to heat generation, regardless of the cutting speed and the speed of the saw; thus making circular saws an appropriate choice for cutting polycarbonates. But, you will need to choose a saw blade with fine teeth, with a standard size saw blade of 250-300 millimeters. Using such a circular saw at a recommended speed of 4000 revolutions per minute, you can get a nice smooth cut. Also, due to the properties of the material, polycarbonate will not crack or crush around the cut. It is the saw that determines the cutting speed and thus the throughput speed, which is around 8 meters per minute, or 10 to 15 centimetres per second.

- Can Polycarbonate be cut by laser ?

Polycarbonate sheet can be cut with industrial cutting lasers however, edges may become amber or brown when laser cut and a clean edge is difficult to obtain. In fact, some laser cutters are not able to cut it because it ruins the lens and requires frequent stopping and cleaning.

|

||||||||||||||||||

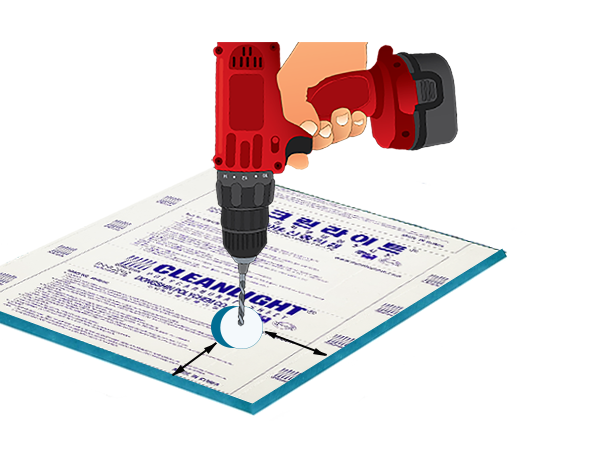

3. Drill

- Remember that polycarbonate sheets naturally expand and contract with temperature. Thus, you will need the correct fixings to allow such expansion and contractions without issues.

- When you drill holes into the polycarbonate sheet to fix them over the structure with screws, you must pre-cut the hole a little wider at least 2mm - 4mm to allow for expansion. This will prevent your sheets from buckling

- When the position of the screw hole is too close to the edge of the polycarbonate solid sheet, it is very easy to cause the broken board. The position of the screw hole should be at least 40 mm from the edge of the polycarbonate solid sheet.

|

||||||||||||||||||

|

4. Screw - When installing, the bolts should not be too tight, otherwise the polycarbonate solid sheet will burst and waterproof problems will occur.

- PVC gasket and the chemical substances in some rubber gaskets will damage the PC solid sheet after contact with the solid PC sheet, so they cannot be used. It is recommended to use Silicone rubber and Neoprene rubber.

- Use only compatible clear silicone for the sealing

|

||||||||||||||||||

|

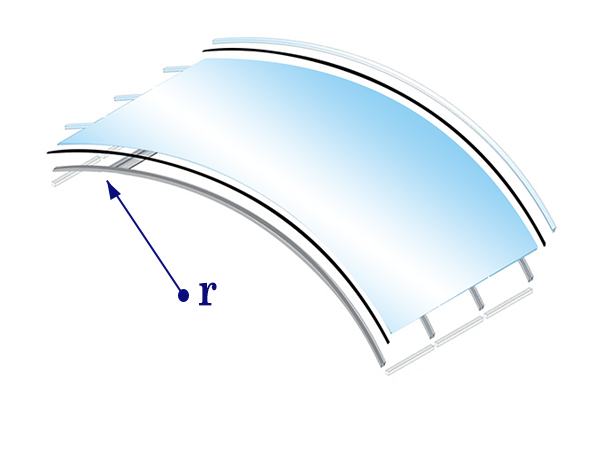

5. Curved roofing - The solid polycarbonate sheets can be cold-curved. Follow the minimum curving radii from the table below.

|

||||||||||||||||||

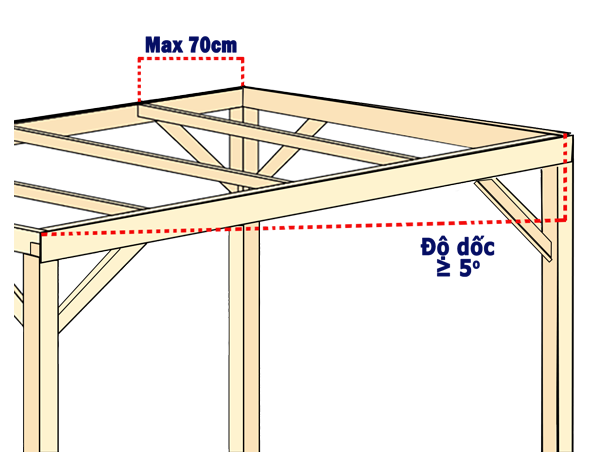

6. Flat roofing

- Make sure that there is a 5° slope when fitting the sheets – this will allow rainwater run off.

- The purlins which of those ones need to be spaced no more than 700mm between each other

- To attach two or more polycarbonate sheets together, you need to use an H-connector. This is used to make the installation fast and easy, and also helps prevent the polycarbonate sheets from detaching and breaking down when drilled. Moreover, it also improves the exterior appeal of your roofing.

- Remember, the polycarbonate H profile, MUST NOT be fastened to the frame.

|

||||||||||||||||||

|

7. You should never walk on polycarbonate roofing unless it’s well-supported underneath. Even polycarbonate is strong, it’s not meant to support the weight of a person. The surface is slippery and you will likely fall. Further, you can scratch it if you walk on it. |

Chia sẻ :